Unleash your creativity with custom design and on-demand jewelry production with full customization, instant pricing, no minimums print on-demand dropshipping and fast turnarounds.

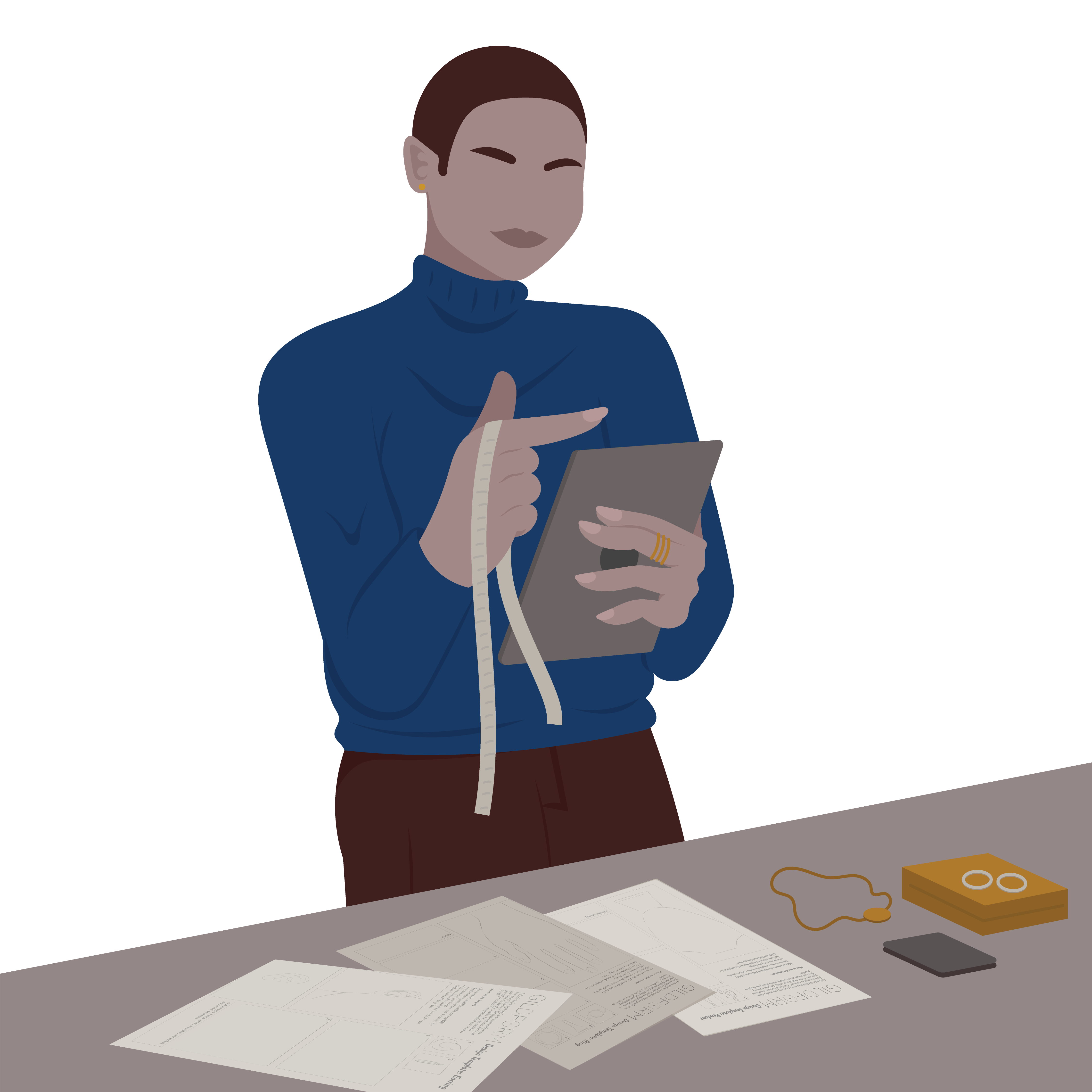

Custom Earring Design

by Ouro & Kin

Create your jewelry from concept to creation starting with a sketch and/or reference images.

Launch or scale your brand on your own terms. Pay-as-you-go when manufacturing your fully customized jewelry with the Gildform: Print On-Demand App exclusively on Shopify.

Upload your 3D models, select your specifications and get instant, quantity-based pricing for manufacturing your jewelry. Get started for free with no-minimum requirements on eligible orders.

Design, produce and fulfill orders for your jewelry products faster than ever before! Eligible orders may ship within 10 working days or less with priority turnaround options and with all dropshipped orders from Shopify.

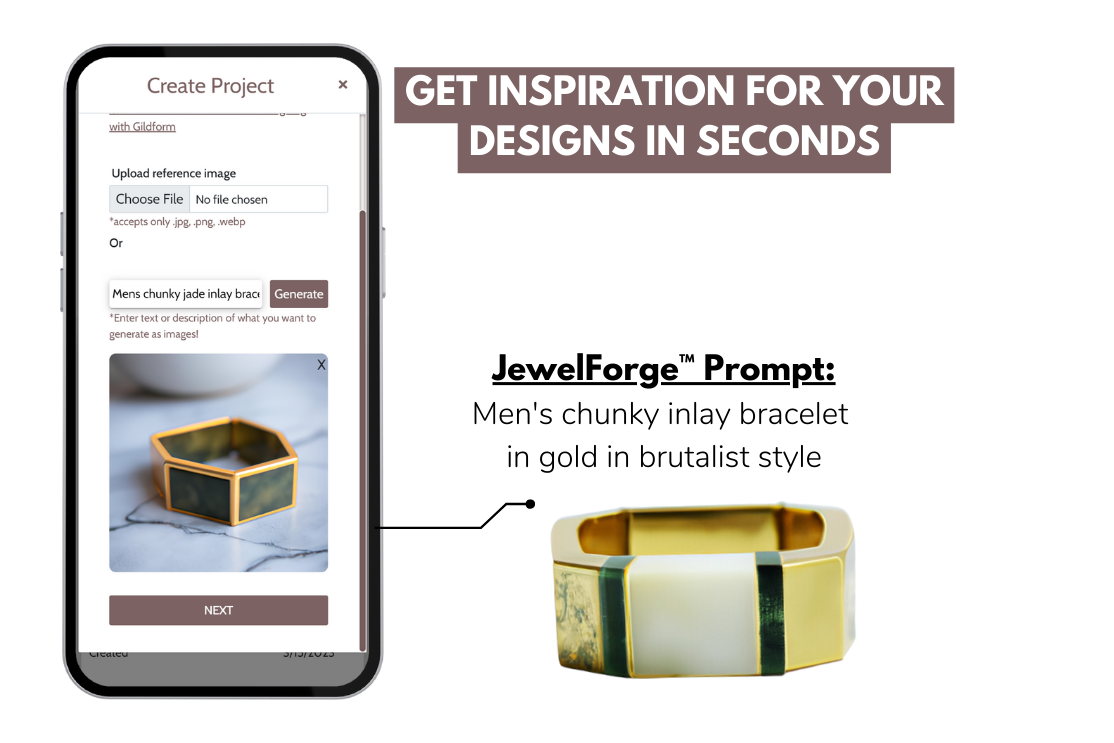

Discover the power of JewelForge and BrandForge, AI-driven tools that help creators design unique jewelry and build strong brand identities. Explore their features and benefits today!

Check out the amazing jewelry made by our creators and powered by Gildform.

They are creators (just like you!) that use Gildform to design, produce, package and fulfill their jewelry from concept-to-creation.

Are you inspired? We know we are.

Gold Snake Earring by FIYA LAUR

Nella Nameplate by BROOK AND YORK

Melanin Dog Tag by EUMELANIN

Beaded Hoop Ear Jacket by WELLTHY

Naag Nool Necklace by FIYA LAUR

Nella Nameplate Ring by BROOK AND YORK

Gold Snake Earring by FIYA LAUR

For Gildform, on-demand jewelry manufacturing means unlimited possibilities. The freedom to dream, design, produce and sell products without the limitations that come with the lack of materials, the lack of technical design experience, or the lack of skilled staff.

Apply up to $50K in financing for your jewelry design and production with Gildform.

Get the funds you need, right when you need them and take out the guess work when it comes to funding your jewelry line.

Discover the power of JewelForge and BrandForge, Gildform’s AI-tools that can help you design unique jewelry and build strong brand identities.

Explore their features and benefits today!

We’re glad you asked. We have a team of really amazing expert jewelers based in Detroit, MI producing your jewelry. Every piece is 3D printed, cast, polished and assembled in Detroit, MI.

Once you’re satisfied with your 3D model, its materials, and quantity we’ll start producing your order. The Gildform manufacturing process starts with 3D printing and lost-wax casting and ends with precise finishing and polishing based on your specifications. Read more about our jewelry manufacturing process on our process page

A 3D Model is a CAD file which stands for computer-aided design, the technology many experts believe will be the primary process of jewelry design and manufacturing in the near future. As technology progressed, it became possible to create three-dimensional “models” of virtually any design within the computer environment.

For the bench jeweler, CAD modeling onscreen has much in common with lost wax casting and shares similar benefits as well. Once the virtual model is finished to the technician’s desire, the CAD file may be sent to a CAM machine for production.

There are many advantages of CAD/CAM over traditional manufacturing methods. CAD files can also be copied, changed, and saved as often as the designer chooses. A model can be designed and saved, then redesigned to allow for a limitless set of variations on the original design.

In addition to its’ manufacturing advantages, CAD software works in tandem with high-tech rendering software to make spectacular realistic images of jewelry models before the actual piece is made.

The 3D printing process builds a three-dimensional object from a computer-aided design model, usually by successively adding material layer by layer, which is why it is also called additive manufacturing

3d printing is the process of making a three-dimensional object from a computer-aided design file. The three-dimensional object is usually created by successively adding material layer by layer until the object is completed.

3D printing will produce a real, solid piece of jewelry with a smooth surface. The object can also be finished manually with post-processing depending on your desires.

Lost-Wax Casting is an age-old technique that has been used to create jewelry for centuries, dating back to Ancient Egypt. This precision casting technique is used for transmuting wax models and/or castable resins created using our 3-D Printing Technologies into your desired metal.

Lost-Wax Casting can also be used for any pieces that are intricately designed or filigreed due to the wax mold’s ability to be finely imprinted. The resin that is used in lost-wax casting burns out cleanly leaving no ash residue. This technique is perfect for anyone that wants their finalized product to be highly detailed.

Your initial 30 min consultation is free of charge. During these consultations, we get to know you, your brand, and your production needs in order to make sure Gildform is the best match. If you decide that further consultation is for you, the cost will be separate from the cost of your order.

Setting up a free Gildform account gives you access to the full benefits of our web app. Once we’ve been formally introduced, you’ll have a manufacturing partner that can carry your vision from CAD file to finished product.

Be sure to choose the *Standard* membership during the last step of your sign-up. Until you make a purchase, your credit card info is only used to ensure that you’re a real person (bots usually don’t have credit cards).

Sketches are always welcome, the more detailed the better. We’ll use your sketch to create a CAD file of your design. You can upload a sketch here for a CAD file quote.

Great! All you need to do from here is to Create An Account and upload your CAD files. Once you upload your CAD files, select your materials, polishing specifications and assembly for an instant price to the metals market. Don’t forget to enter in your preferred quantity, as prices will change based on how many units you order.

After you’ve uploaded the 3D model, we use our proprietary pricing algorithm to determine the most transparent pricing based on the 3D files uniquely encoded information instantly. Once our software knows this information, we’re able to give you the price of your selected material (to the metals market) and the price for polishing and assembly.

However, for the best quality jewelry products we ask for a 1 mm minimum wall thickness for all areas in the 3D models that you upload onto Gildform. If in the event your 3D Model presents issues in the manufacturing process or is Not Optimized for Production or overall not producible, we will reject the order and refund the cost of the item that is not optimized for production, minus the Restocking Fee.

Please Note: There is a Restocking Fee for each item that has been rejected due to being deemed Not Optimized for Production. The Restocking Fee is 15% of the total cost of each item that is Not Optimized for Production.

We can not guarantee that your 3D file(s) will be optimized for production and have all the necessary allowances for shrinkage, polishing, etc.

Your model may shrink ~0.25 mm plus ~2.5-5% after casting and finishing. For rings the inner diameter is accurate within +/- 0.1 to 0.15mm. The model typically shrinks about ~2.5-5% after casting and finishing. We do our best to polish your pieces to match your model file(s). However, we cannot guarantee that your model accounts for this shrinkage and polishing. By working with a Gildform designer, you will be certain that your CAD file is ready for production with the necessary tolerances for 3D printing and polishing. If you’d like us to inspect your CAD file before placing your order, email us your 3D file to hello@gildform.com. The cost for inspection is $35 per 3D file.

We will inform you if your design requires a remodel to be better optimized for production.

Gildform doesn’t do “minimum orders.” Whether your order is one piece or 1,000, we’ll print it, cast it, finish it and ship it to your door with the Standard Plus account.

Yes! Just enter your desired quantity in the quantity field under the 3D model are, and like magic, your price per unit will change due to our ability to disburse set up costs amongst each unit. (hint: the more units you order, the lower the cost will be per unit)

Once you’ve submitted an order for on-demand manufacturing, we begin producing the order to your specifications. We are not able to make modifications to your order once it’s been placed.

Once we have a workable 3D model that meets your standards and ours, It’s time to make your purchase and get your order started. Once we’ve received your payment, your new manufacturing team will start 3D printing your order.

With our production tracking feature, you’ll be able to follow your order from start to finish. Once you log into your account you’ll be able to view the latest progress for your order. If there are any delays we won’t hesitate to reach out using the contact info you’ve provided.

Yes! Once you’ve created your Gildform account, your order history will be saved and you’ll be able to repeat any order in just a few clicks.

You can email us at hello@gildform.com , or you can call us at 313-782-4293.